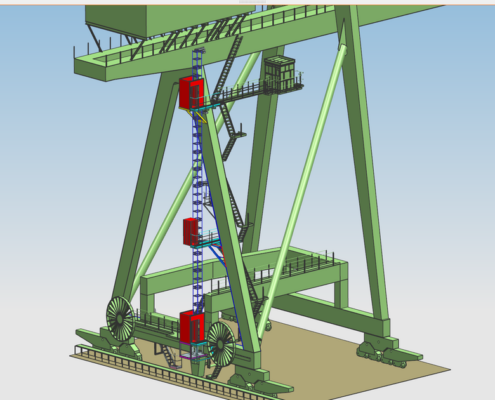

Another Milestone for Portek – MICT QC7 Refurbishment project

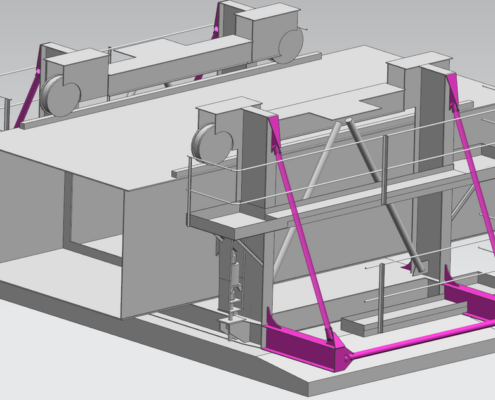

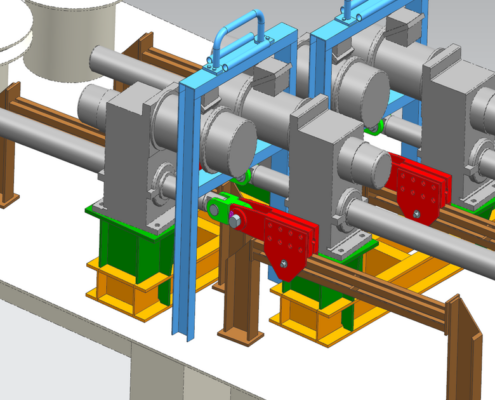

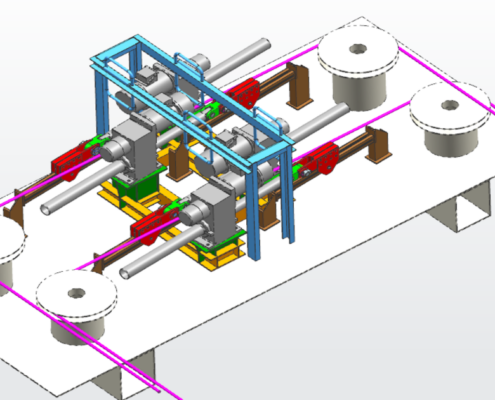

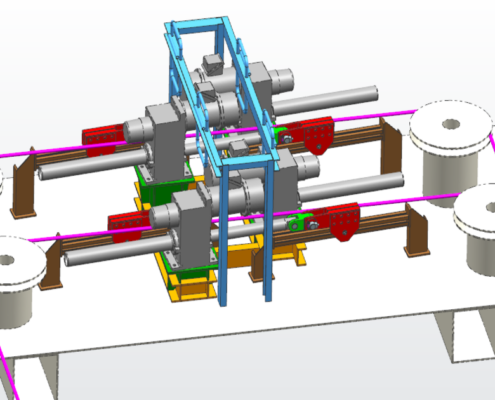

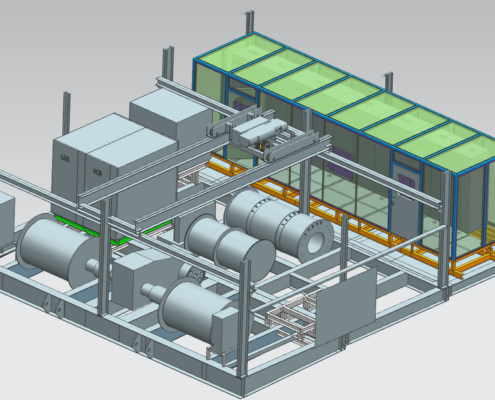

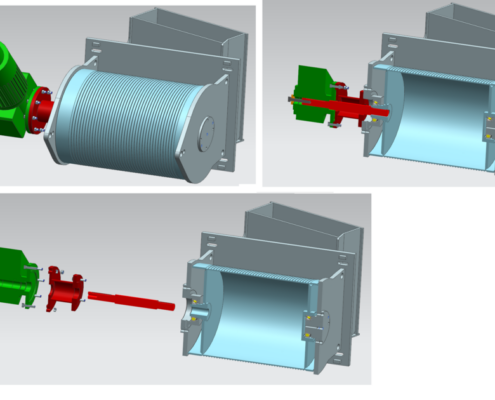

Portek has reached another milestone in performing crane refurbishment projects as one of the leaders in port equipment engineering works. We have just successfully completed QC7 refurbishment project at ICTSI (International Container Terminal Inc.) in Manila, Philippines.

Despite surging Covid cases in Manila, and some team members had gone down with the infection, our team had managed to brave the difficult situation, delivered the quality work to the satisfaction of the customer, and completed the project on-time. After the successful commissioning and the endurance test, we have conducted a technical training for the relevant personnel at MICT.